|

CD Storage Chest

The

basic problem was simple - I needed a rack to hold my growing

CD collection. The real problem was that I didn't like any

of the typical CD holders I saw in stores. The vast majority

of them had two things in common - (1) they tended to be tall,

shallow and thus unstable, (2) they held the CD on-edge so

that all that could be seen is that narrow strip of text on

the spine of the plastic jewel case. I wanted something sturdy

enough to stand on its own without fear of toppling over due

to an accidental bump and I like seeing the covers.

As

it turns out, solving the latter problem also takes care of

the former. To see the CD covers, I decided to use flip-style

CD holders. These are available from many hobby and woodworking

suppliers. The ones I used hold 20 CDs and measure about 14

inches in length. That length, combined with the rest of the

structure guaranteed an overall heft large enough to be extremely

stable.

Below

is a brief description of the unit as I built it. The only

pictures I have were taken after the unit was completed so

there are no pictures of intermediate construction steps.

The unit itself is scalable - both in terms of capacity and

in terms of construction quality and appearance. More on this

later. I won't provide step-by-step instructions on making

one of these units. Instead I'll provide information on what

I did to get the end product. This should allow anyone to

adapt the design to fit individual needs. All measurements

are approximate as everything is ultimately made to fit, not

to some preconceived measurement.

Overall

Dimensions - Approximately 33-1/2 inches wide (including

overhang of top), 18-1/4 inches deep (including overhang of

top), 34-1/4 inches tall.

Basic

Materials - Low cost is good. The bulk of the unit is

made from one 4ft x 8ft x 3/4 inch sheet of furniture grade

oak plywood. This sheet was ripped to form four drawers bottoms,

four drawer fronts and two side panels. The rear is made from

two 2ft x 4ft sheets of 1/16 inch of hardboard

(my local Home

Depot didn't have 4x4 sheets and 2 smaller sheets were

easier to carry in my car). The top is two laminated sheets

- 1/2 inch furniture grade oak plywood and 3/8 inch furniture

grade cherry veneered plywood. Both are leftovers from other

projects. The rest of the visible wood is random leftover

cherry and mahogany.

Using

furniture grade veneered plywood greatly simplified the overall

construction - the veneer looks great and I didn't have to

worry about wood movement (from environmental changes) on

the side panels.

The

Drawers - The drawers are the heard of the unit so they

were designed first. Everything else simply wraps the drawers.

The unit has four drawers, each holds 5 flip style trays of 20

CDs each. The overall capacity is 400 CDs (100 per drawer). Each drawer

sits on full-extension slides.

This is important - you want to be able to reach the very

last CD and regular 3/4 extension drawers won't let you do

that unless you give each drawer lots of extra height clearance

for your hand to reach the rear. I bought my drawer slides

from Woodworker's

Hardware.

The unit has four drawers, each holds 5 flip style trays of 20

CDs each. The overall capacity is 400 CDs (100 per drawer). Each drawer

sits on full-extension slides.

This is important - you want to be able to reach the very

last CD and regular 3/4 extension drawers won't let you do

that unless you give each drawer lots of extra height clearance

for your hand to reach the rear. I bought my drawer slides

from Woodworker's

Hardware.

Each drawer is entirely open except for the front. There are no

sides or back. I did this purely for construction simplicity.

The drawer slides are screwed directly into the 3/4 inch drawer

bottom's (plywood) edges. The drawer front is also made from

the same 3/4 inch plywood and is screwed into place from the

front with 3 screws. The screws are then covered with a strip

of cherry acting as an accent piece. Since the drawer pull

sits about 2 inches above the drawer bottom I added two metal

"L" brackets on the drawer's inside to prevent torque

on the drawer pulls from ripping the drawer fronts off. This

is especially important since most drawer slides have a notch

in the closed position that requires an extra tug to open.

The "L" bracker is a 1 inch x 1/2 inch unit from

the local ACE

Hardware store. Aside from stiffening the drawer front,

it also helps align the front to be perpendicular to the drawer

bottom. The

drawer pulls were a clearance item from

Lowe's.

Each drawer is entirely open except for the front. There are no

sides or back. I did this purely for construction simplicity.

The drawer slides are screwed directly into the 3/4 inch drawer

bottom's (plywood) edges. The drawer front is also made from

the same 3/4 inch plywood and is screwed into place from the

front with 3 screws. The screws are then covered with a strip

of cherry acting as an accent piece. Since the drawer pull

sits about 2 inches above the drawer bottom I added two metal

"L" brackets on the drawer's inside to prevent torque

on the drawer pulls from ripping the drawer fronts off. This

is especially important since most drawer slides have a notch

in the closed position that requires an extra tug to open.

The "L" bracker is a 1 inch x 1/2 inch unit from

the local ACE

Hardware store. Aside from stiffening the drawer front,

it also helps align the front to be perpendicular to the drawer

bottom. The

drawer pulls were a clearance item from

Lowe's.

The

drawer front is 30 inches wide 6-3/8 inches high. Each slide

is 1/2 inch deep so the drawer bottom is 29 inches wide and

15-1/2 inches deep. This depth was chosen based on (1) the

16 inch length of the slides and (2) the 14 inch length of

the CD tray. Note that the drawer front extends below the

drawer bottom by about 1/2 inch. This was done to guarantee

that the slides would clear the top of the next lower drawer

(the slides are taller than the 3/4 inch thickness of the

drawer bottom). This may seem confusing until you hold an

actual full extension side and fully extend it. The height

above the drawer bottom is about 5-1/4 inches which is enough

for the CD and CD tray.

Each

drawer front has iron-on veneer applied to the top and sides

to cover the exposed plywood edges.

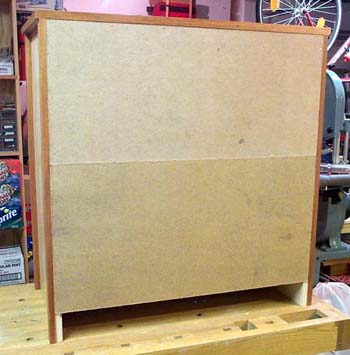

Side Panels

- The sides are about as simple as can be.

Each is a single sheet of 3/4 inch plywood extending from

top to bottom. The four corners are trimmed with 3/4 inch

mahogany to give the apperance of "legs" and to

hide the exposed plywood ends. The picture from the rear

shows the applique.

Side Panels

- The sides are about as simple as can be.

Each is a single sheet of 3/4 inch plywood extending from

top to bottom. The four corners are trimmed with 3/4 inch

mahogany to give the apperance of "legs" and to

hide the exposed plywood ends. The picture from the rear

shows the applique.

Bracing

and Stability - Since all the weight rests on the sides

via the drawer slides, it's important that the side panels

transfer the load straight down and not wobble side to side.

On the front, the two side panels are held in place by 3/4

inch (plywood) beams at the top and middle and a 6 inch kickboard

at the bottom. I decided against recessing the kickboard since

that would only complicate the construction of the side panels.

The rear has the same side-to-side beams at the top and middle.

The bottom is a little different - there is a small shelf

that keep the side panels from twisting. At the top, the top

panel acts to prevent this twisting motion.

Back - The back is extremely simple. Here is a view.

Two pieces of 1/16 inch thick hardboard span almost the entire

space. No rabbets were cut to hide the hardboard; rather the

side panel applique simply covered the hardboard edges. The

two pieces meet at the middle rear beam.

Back - The back is extremely simple. Here is a view.

Two pieces of 1/16 inch thick hardboard span almost the entire

space. No rabbets were cut to hide the hardboard; rather the

side panel applique simply covered the hardboard edges. The

two pieces meet at the middle rear beam.

|