|

3-Way High Efficiency Speaker

3-Way High Efficiency Speaker

(Lavoce, Dynaudio, Foster 3-way. October-2023)

LCR MTM 3-Channel Speaker

LCR MTM 3-Channel Speaker

(Three MTM Speakers in One. July-2023)

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

(Minimus 7 and Dayton Audio. Spring-2022)

2-Way Ribbon Tweeter Speakers

2-Way Ribbon Tweeter Speakers

(Vifa and Pioneer. May-2020)

Transmission Line Speakers

Transmission Line Speakers

(Aborted attempt at a TL. September-2012)

Acoustic Research AR-4x Rehab

Acoustic Research AR-4x Rehab

(Rehab of a garage sale find. January-2016)

Infinity RS-4000 Rehab

Infinity RS-4000 Rehab

(Rehab of a garage sale find. June-2015)

Polaris

Polaris

(A tall, thin, upwards firing omnidirectional speaker. May-2010)

Shiva_PR15

Shiva_PR15

(A powered subwoofer using a 12" driver and 15" passive radiator. Jan-2010)

Can-Less

Can-Less

(A computer speaker; redux. December-2005)

Can-Can

Can-Can

(A computer speaker in a light canister. Jan-2005)

Sonosub

Sonosub

(10" vented subwoofer in a cardboard tube, powered by a Parapix amp. May-1999)

MTM Center Channel Speaker

MTM Center Channel Speaker

(A Madisound design. Nov-1997)

2-way Surround Speakers

2-way Surround Speakers

(5" woofer and 1" tweeter. July 1997)

3-piece mini system

3-piece mini system

(6" DVC bass module mated to 4" car speaker. June 1997)

3-way Vented Floorstanding Speaker

3-way Vented Floorstanding Speaker

(vented 10" woofer, 5" mid and 1" tweeter in a 4

ft tower. Summer 1995)

NHT1259 Subwoofer

NHT1259 Subwoofer

(A 12" woofer in a sealed architectural pedestal. Winter 1994-95)

Inexpensive Speaker Stands

Inexpensive Speaker Stands

(Particle board, sand and spray paint. Fall 1994)

2-way satellite

2-way satellite

(6.5" woofer and 1" tweeter. Summer/Fall 1994)

| Audio Electronics Related Projects |

900 MHz Audio Receiver

900 MHz Audio Receiver

(Better use for bad headphones. Jan-2008)

Buster - A Simple Guitar Amp

Buster - A Simple Guitar Amp

(Perfect for the beginner. Jan-2010)

A PC-based Audio Console

A PC-based Audio Console

(Use a PC to play tunes. Jan-2010)

LM-12 Amp

LM-12 Amp

(Bridged LM-12 opamps. Aug-2003)

CeeDeePee

CeeDeePee

(A CD player and FM tuner from spare computer parts. Oct-2002)

Quad 2000 4-Channel Amp

Quad 2000 4-Channel Amp

(Premade modules by Marantz. May-1998)

Zen Amp and Bride of Zen Preamp

Zen Amp and Bride of Zen Preamp

(by Nelson Pass. Apr-1997)

Using Wood in Speakers FAQ

Using Wood in Speakers FAQ

(Work in progress)

MDF FAQ for speaker builders

MDF FAQ for speaker builders

Woodworking Tools for the DYIer

Woodworking Tools for the DYIer

(HomeTheaterHiFi.com Oct-1998)

Some Thoughts on Cabinet Finished for DIY Speakers

Some Thoughts on Cabinet Finished for DIY Speakers

Large Grills Made Easy

Large Grills Made Easy

Some Parts Suppliers

Some Parts Suppliers

(Outdated)

DIY Audio Related URLs

DIY Audio Related URLs

Veneering Primer

Veneering Primer

(by Keith Lahteine)

How to get a Black Piano Finish

How to get a Black Piano Finish

(by DYI Loudspeaker List members)

Sonotube FAQ

Sonotube FAQ

(by Gordon McGill)

Excerpts from the Bass List

Excerpts from the Bass List

(Oldies but Goodies)

DIY Loudspeaker List Archives

DIY Loudspeaker List Archives

|

|

LM12-based Amplifier

Some projects

just seem to take longer than others; and by the time they're

done, their reason for existing has long since come and gone.

This is what happened to this amplifier - a project that grew

out of a need for some cheap power which eventually turned

into a project to get rid of unused parts. But I'm getting

a little ahead of myself.

History

Back in

the mid 90's when I first started to assemble my NHT1259-based

subwoofers, I reasoned that if I could build a pair of

cheap but reasonably powerful amplifiers, not only would I

save a $ or two, but I'd also have the satisfaction of building

it. A few other DIYers had successfully built subwoofer amps

using dual LM12 op-amps in a bridged configuration. I obtained

three free samples from National Semiconductor (free is always

good for the DIYer !) and decided to start construction.

Some plans

just don't seem to work out no matter how hard one tries.

In this case, I had trouble getting all the parts I needed,

especially a large enough heatsink and transformer. Oh, did

I say I wanted them cheap ? Ideally, I wanted a transformer

that would deliver about 20 to 22V (40VAC CT) with a decent

amount of current (8A min). This would yield a DC voltage

near the maximum normal operating range of the LM12. A standard

48VAC CT transformer would be to large, and some DIYers had

run into device failures when pushing the standard LM12 (there

are some higher voltage parts available). Getting a transformer

of suitable size is normally not a big deal, but getting it

cheap and not having a timetable for the project meant that

I never found what I wanted. I couldn't find any in the surplus

outlets and I dismissed the thought of unwinding a large transformer.

Over time,

my NHT1259 subwoofers were done and put into service. I no

longer needed this amp and so the plans were shelved. In the

late 90's Adire

Audio released their Shiva subwoofer driver and offered

the DIY Speaker List an introductory special. I decided that

a dedicated subwoofer for a home theater LFE channel would

be something neat to build and so the LM12 amp had a new purpose

in life. As luck would have it, my overall home theater project

never came to be and so I now have both the Shiva and the

LM12 project sitting on ice.

On the parts

front, I stumbled across some large heatsinks with predrilled

TO-3 holes in a surplus outlet in Manchester NH. My project

suddenly was alive... well sort of. The final piece of the

puzzle came from Surplus

Sales of Nebraska. They had a 38VAC CT transformer rated

at 10 A for $35. Now that I had all my parts, I started assembly.

Things immediately ground to a halt when I prototyped a single

op-amp circuit. The gain was set to just 3 and the resulting

noise was pretty bad. Dissapointed, I put off the project

rather than taking the time to debug it; what's the rush since

it's been so long already ? I picked up the project and this

time set the gain to 20 (a more reasonable value for an amp).

I cleanup the connections and things sounded pretty good.

Before continuing, I decided to envision the entire thing

- what would the completed amp look like ? Can I use it as

a unit mounted into the rear of a subwoofer (like a "plate"

amplifier) ? What about a preamp circuit for level matching

? What about EQ for the sub ? All these design questions once

again stalled the project.

Meanwhile,

the Shiva project lumbered

along at a turtle's pace. It too lacked direction and spent

most of its time either collecting dust or sitting in a test

box that in turn collected dust. Without my desired home theater

setup visible in the near future, there was no incentive to

work on the subwoofer. The further complicate matters, the

original plan of building a passive radiator subwoofer in

a small box now seemed less than ideal. The simulation response

curves weren't all that I wanted for the box size I had hoped

for... it was all going nowhere.

Reality

finally set in. I had to put these projects aside to make

room for other projects; and the best way to do that was to

finish them. With some unresolved questions still lurking

in the background, the smart thing to do seemed to be to package

up both the LM12 and the Shiva project into a semi-finished

state in the quickest, most cost effective manner. For the

LM12, this meant housing it so that it could be used if necessary

but not in anything fancy in case I ever decide to re-house

it some day. So here it is, two large heatsinks bolted together,

then screwed to a piece of plywood. The enclosure has 4 sides.

It is missing a top and most of the back. It is fully wired

but has not preamp, crossover or EQ functionality. All that

is for the future, whever that is !

Construction Details

The details

here are a little sparse because, frankly, there's not much

to say !

The design

is the basic LM-12 amplifier circuit as published in the LM-12

specifications from National

Semiconductor. I used the bridged design, using two LM12s

for a single channel (one inverted, one non-inverted). The

voltage gain is set to 20.

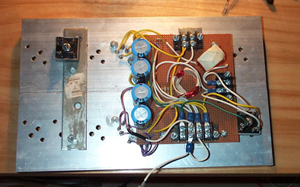

This is the heatsink assembly.

The circuit board doesn't hold much - just a few passive parts

and electrical connectors. I could have easily bolted a few

terminal strips to the back of the heatsinks and performed

the same point-to-point wiring but this looks a little cleaner.

The are three sets of screw terminals. Towards the bottom

is a set of four for the power supply. The (+, -, and two

for ground). The two screws near the top is the input signal.

Finally, the two near the right edge is the output to the

speaker. The bridge rectifier on the right is on the output

to the speakers. The unconnected bridge rectifier on the left

is for the main power supply. The heatsink is electrically

isolated from all components (bridges and LM12).

This is the heatsink assembly.

The circuit board doesn't hold much - just a few passive parts

and electrical connectors. I could have easily bolted a few

terminal strips to the back of the heatsinks and performed

the same point-to-point wiring but this looks a little cleaner.

The are three sets of screw terminals. Towards the bottom

is a set of four for the power supply. The (+, -, and two

for ground). The two screws near the top is the input signal.

Finally, the two near the right edge is the output to the

speaker. The bridge rectifier on the right is on the output

to the speakers. The unconnected bridge rectifier on the left

is for the main power supply. The heatsink is electrically

isolated from all components (bridges and LM12).

|

|

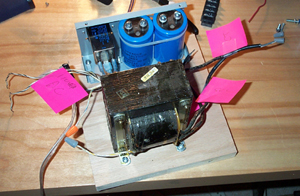

This is the power

supply assembly. The pink PostIt notes identify the transformer's

secondary to be used by the LM12s. There is also another unused

secondary winding (orange and grey wire nuts on the left side).

The metal plate near the top is part of an old ATX computer

power supply. I originally intended to mount various components

in the ATX chassis but decided at the last minute to scrap

the idea. I ended up using part of it so that I could easily

mount an EIC receptable, an accompanying line filter and the

main power supply caps. Since this whole box is temporary,

it's no big deal.

This is the power

supply assembly. The pink PostIt notes identify the transformer's

secondary to be used by the LM12s. There is also another unused

secondary winding (orange and grey wire nuts on the left side).

The metal plate near the top is part of an old ATX computer

power supply. I originally intended to mount various components

in the ATX chassis but decided at the last minute to scrap

the idea. I ended up using part of it so that I could easily

mount an EIC receptable, an accompanying line filter and the

main power supply caps. Since this whole box is temporary,

it's no big deal.

|

|

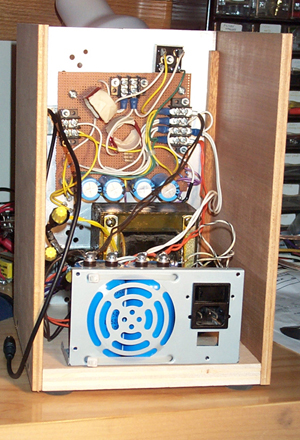

The heatsink assembly

is screwed to the plywood base of the power supply assembly.

Two screws is all it takes. All wiring is removable.

The heatsink assembly

is screwed to the plywood base of the power supply assembly.

Two screws is all it takes. All wiring is removable.

|

|

The side panels are

just pieces of plywood. Four rubber feet at added to raise

the unit. The black cable on the left side is connected to

the input screw terminals; the other end has a female RCA

connector.

The side panels are

just pieces of plywood. Four rubber feet at added to raise

the unit. The black cable on the left side is connected to

the input screw terminals; the other end has a female RCA

connector.

|

|

The front view.

The front view.

|

|

03-August-2003

Note: The

contents in these pages are provided without any guarantee,

written or implied. Readers are free to use them at their

own risk, for personal use only. No commercial use is allowed

without prior written consent from the author.

|

|

|