|

3-Way High Efficiency Speaker

3-Way High Efficiency Speaker

(Lavoce, Dynaudio, Foster 3-way. October-2023)

LCR MTM 3-Channel Speaker

LCR MTM 3-Channel Speaker

(Three MTM Speakers in One. July-2023)

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

(Minimus 7 and Dayton Audio. Spring-2022)

2-Way Ribbon Tweeter Speakers

2-Way Ribbon Tweeter Speakers

(Vifa and Pioneer. May-2020)

Transmission Line Speakers

Transmission Line Speakers

(Aborted attempt at a TL. September-2012)

Acoustic Research AR-4x Rehab

Acoustic Research AR-4x Rehab

(Rehab of a garage sale find. January-2016)

Infinity RS-4000 Rehab

Infinity RS-4000 Rehab

(Rehab of a garage sale find. June-2015)

Polaris

Polaris

(A tall, thin, upwards firing omnidirectional speaker. May-2010)

Shiva_PR15

Shiva_PR15

(A powered subwoofer using a 12" driver and 15" passive radiator. Jan-2010)

Can-Less

Can-Less

(A computer speaker; redux. December-2005)

Can-Can

Can-Can

(A computer speaker in a light canister. Jan-2005)

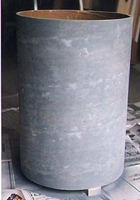

Sonosub

Sonosub

(10" vented subwoofer in a cardboard tube, powered by a Parapix amp. May-1999)

MTM Center Channel Speaker

MTM Center Channel Speaker

(A Madisound design. Nov-1997)

2-way Surround Speakers

2-way Surround Speakers

(5" woofer and 1" tweeter. July 1997)

3-piece mini system

3-piece mini system

(6" DVC bass module mated to 4" car speaker. June 1997)

3-way Vented Floorstanding Speaker

3-way Vented Floorstanding Speaker

(vented 10" woofer, 5" mid and 1" tweeter in a 4

ft tower. Summer 1995)

NHT1259 Subwoofer

NHT1259 Subwoofer

(A 12" woofer in a sealed architectural pedestal. Winter 1994-95)

Inexpensive Speaker Stands

Inexpensive Speaker Stands

(Particle board, sand and spray paint. Fall 1994)

2-way satellite

2-way satellite

(6.5" woofer and 1" tweeter. Summer/Fall 1994)

| Audio Electronics Related Projects |

900 MHz Audio Receiver

900 MHz Audio Receiver

(Better use for bad headphones. Jan-2008)

Buster - A Simple Guitar Amp

Buster - A Simple Guitar Amp

(Perfect for the beginner. Jan-2010)

A PC-based Audio Console

A PC-based Audio Console

(Use a PC to play tunes. Jan-2010)

LM-12 Amp

LM-12 Amp

(Bridged LM-12 opamps. Aug-2003)

CeeDeePee

CeeDeePee

(A CD player and FM tuner from spare computer parts. Oct-2002)

Quad 2000 4-Channel Amp

Quad 2000 4-Channel Amp

(Premade modules by Marantz. May-1998)

Zen Amp and Bride of Zen Preamp

Zen Amp and Bride of Zen Preamp

(by Nelson Pass. Apr-1997)

Using Wood in Speakers FAQ

Using Wood in Speakers FAQ

(Work in progress)

MDF FAQ for speaker builders

MDF FAQ for speaker builders

Woodworking Tools for the DYIer

Woodworking Tools for the DYIer

(HomeTheaterHiFi.com Oct-1998)

Some Thoughts on Cabinet Finished for DIY Speakers

Some Thoughts on Cabinet Finished for DIY Speakers

Large Grills Made Easy

Large Grills Made Easy

Some Parts Suppliers

Some Parts Suppliers

(Outdated)

DIY Audio Related URLs

DIY Audio Related URLs

Veneering Primer

Veneering Primer

(by Keith Lahteine)

How to get a Black Piano Finish

How to get a Black Piano Finish

(by DYI Loudspeaker List members)

Sonotube FAQ

Sonotube FAQ

(by Gordon McGill)

Excerpts from the Bass List

Excerpts from the Bass List

(Oldies but Goodies)

DIY Loudspeaker List Archives

DIY Loudspeaker List Archives

|

|

Sonosub

- An Inexpensive Powered Subwoofer

Introduction

This article

outlines the construction of the Sonosub, a

low cost subwoofer, complete with power amplifier.

This projects

started out as a subwoofer for my home theater (HT). After

I started working on it, I decided against having yet another

box in the room so I decided to give it to my brother for

his HT system. Along the way I learned a few things about

working with tubular enclosures.

While the

results were ultimately satisfactory, several mistakes were

made during construction that could have made the subwoofer

better than it is. This article describes both what I did

as well as what I probably should have done. Learning often

means making mistakes and I don't mind making them if it means

I will avoid them the next time around. Hopefully, readers

will benefit from my mistakes as well by extracting those

aspects of the design they find useful, and ignoring the questionable

parts.

For the

curious, here's what everything looked like at the end.

Design

Goals and Criteria

During part

of 1998, Madisound

sold a driver named the INF-10 at a mere $34 USD. These are

10 inch drivers manufactured by Infinity

Systems. During this time, I became interested in the

construction of cylindrical speaker enclosures. Subwoofers

made from Sonotube, a commercial cardboard tube made

for pouring concrete footings, are fairly popular with the

DIY speaker crowd due to their low cost, simplicity, and high

performance. I decided that the INF-10 driver would be perfect

for a low cost tubular subwoofer.

For more

information on Sonotube subs, check out the Sonotube

FAQ by Gordon McGill.

As with

all my projects, I start with a list of goals which then guides

my design.

- Low

cost. When I started this project, I didn't have a real

need for another subwoofer as I already have a

pair of subs utilizing the NHT 1259. But since my subs

are wired to my main speakers (left/right), I figured this

sub could be connected to the subwoofer output of my Pro-Logic

decoder. Since this was targeted at home theater use and

not for high fidelity, I was willing to sacrifice some quality

for cost.

- Easy

to build. Nothing overly fancy. A tube is about as simple

as it gets, though it turned out to be more difficult to

work with than I had anticipated. This may have been partly

due to the 1/2 inch tube I used instead of the typical 1/4

inch tube. The need to provide an appealing finish also

affected the construction steps, making assembly more difficult.

- Use

existing parts where possible. If you like making stuff,

you know what I mean when I say that I always seem to have

"stuff lying around" waiting to be used. This

goal is also consistent with #1 above.

- Low

end extension to at least 30 Hz. This is, after all,

a subwoofer, so let's make sure it sounds like one.

- Aesthetically

pleasing. Looks count. To me, completing a project means

that it's not only useable, but also presentable. This is

important for SAF :)

- Amplifier

and crossover electronics. Can't forget this. In keeping

with goal #1, the original intent was to use a pair

of National

Semiconductor LM-12 high power op-amps in bridged mode.

I already had a pair... somewhere. All I had to do was build

a multiple-input, variable gain, variable frequency, low-pass

crossover and preamp to drive the LM-12s. This idea was

eventually scrubbed in favor of a Parapix amplifer from

Apex Jr.

The Parapix solution was not only cheaper but required much

less work on my part.

- Downward

firing. A downwards firing subwoofer has some advantages

and disadvantages over a forward firing sub. In this case,

firing down made sense due to the use of the tube. It also

meant not having to worry about grills or prodding fingers

from kids (hopefully). Not all drivers should be used in

a downwards firing position, as this will cause cone sag

over time. How the INF-10 will fare over time, I don't know.

- Decent

SPL capabilities. It needs to have enough output to

enjoy movies.

Technical

Details and Design

Here are

the specs for the INF-10 as published by

Madisound.

I did not measure the actual driver used.

| Impedance |

Fs |

Qts |

Vas |

Xmax |

Efficiency |

Power |

| 8 ohms |

22 hz |

0.34 |

109 liters |

8 mm |

88 dB |

100 W |

The design looks like this :

| Internal Volume |

Port Tuning |

Predicted F3 |

Max SPL @ 30 Hz |

| 2.6 cubic feet |

24 Hz |

26 Hz |

106 dB @ 100 w |

For more

information on the INF-10 driver, see Steve

Houlihan's and Brian

Steele's web sites.

Parts List and Cost

Using the

above guidelines, I assembled parts for the Sonosub from various

sources. Many of the items were things I already had on-hand

(goal #3). Other parts came from the local surplus/recycled

materials dealer.

- 16 inch

(inside diameter) cardboard "storage tube" by

Sonoco, 3 ft long. I found this at a local surplus dealer.

Note that this is not a typical Sonotube. The cardboard

in this tube is 1/2 inch thick, twice the typical 1/4 inch

thick concrete tubes. The thicker wall is nice, but adds

to the weight and is not easy to work with if it's not almost

perfectly round. My tube was almost round. Luckily, the

imperfect parts were at one end, where I was able to simply

shorten the tube by the offending amount. Cost : $2.00

- Funiture

grade plywood in varying sizes averaging 2 ft square. These

also came from the same surplus dealer. Both sides are veneered

with what looks like birch, with an 'A' side and a 'B' side.

Thickness is roughly 3/4 inch though it varied from sample

to sample. Cost : $2.00 per sheet, 2 sheets used.

- Particle

board, 5/8 inch thick. I had remnants of a 2 ft x 4 ft sheet

originally intended for some long-forgotten project. There

was enough for one round endcap. Cost : ?

- Construction

grade plywood, 3/4 inch thick. More remnants. Cost : ?

- 3/8 inch

thick cherry veneered plywood. Yet more remnants. Cost :

?

- Roofing

felt. Leftovers. Cost : ?

- Two 3/8

inch threaded steel rods, 3 ft long; plus washers, lock

washers, and nuts. These came from the local home warehouse.

Cost : $7.00

- An INF-10

driver. Cost : $34, not including s&h.

- A plastic

tube for the vent; 3 inches I.D. by 9 inches long. I was

all set to use a piece of plastic plumbing tube when I realized

I already had just the right size tube. The tube was the

center to a roll of paper from a local paper mill. This

roll happened to be 9 inches wide. Cost : $0.00

- A terminal

cup. I already had one. Cost : ?

- Spray-on

finishes, namely Rustoleum's American Accents Stone Creations

(two cans, $14.00) and Clear Matte spray (one can, $6.00),

plus primer ($3.00). Cost : $23.00

- Ball

feet. A downward firing sub must be elevated. I used four

wooden balls (not entirely round; each had a small flat

part) I already had. I don't know what I originally paid

for them, but I found some at the local crafts store for

about $3.00 each sold as "doll heads". Cost :

$12.00

- Parapix

amplifer, with transformer and wiring connector. At $39.00,

this was a much cheaper and simpler solution than building

my own LM-12 amplifier. The transformer for the LM-12s would

have easily cost $20.00 or more and I would still have a

lot of work to do. With shipping and other charges, the

final cost : $49.00. Note that as of this writing, the Parapix

amplifier is sold out and no longer available from Apex

Jr.

Total cost

is $131.00 of the above itemized goods; darn good for both

a subwoofer and amplifer. Cost could easily have been reduced

further by changing the appearance of the unit - use latex

paint instead of the Stone Creations; use simple wooden blocks

for feet, etc.

Building the Speaker

Below are

the notes I took during construction, plus any tidbits added

via hindsight. The steps are not the most streamlined but

represent the actual steps taken; not the optimal ones. This

gives the feel of what was actually done.

- Note

- in all cutting and milling steps, remember to account

for the "good" side of the stock. Most woodworking

operations have a higher risk of tearing or damaging one

surfaces than the other. Properly orienting the stock can

minimize damage to the important surfaces.

- Make the endcaps.

- Cut

down the tube to the desired length of 24-1/4 inches.

Scribe a line around the tube and cut it with a jigsaw.

Cut from one or both ends of the tube so that any deformation

of the tube (likely near the ends where it's weaker)

is cut off leaving the rounder center portion. Cleaned

up the edge as needed.

- The

tube has an inside diameter of 16 inches. The tube's

wall thickness is 1/2 inch. Each endcap consists of

an inner 16 inch diameter insert and an outer 17 inch

diameter cap.

- Mill

two 16 inch diameter round inserts. I made one from

plywood and one from particle board; it's what I had

on-hand. These must fit snugly inside the tube. Don't

assume the tube is exactly 16 inches in diameter. Make

the inserts to fit, not to what it should be. To determine

the actual inside diameter, I took masking tape, taped

a circle inside the tube until it overlapped itself,

marked the tape where it overlapped, removed it and

measured it with a tape measure. This gave me the exact

circumference. Divide the circumference by pi and get

the diameter.

- In

retrospect, my use of cheap plywood was a bad idea.

While it satisfied my goal of using up stuff I already

had, it lowered the quality of the top endcap. See the

section on results.

-

Mill

the two outer round pieces from cabinet grade plywood.

One is the baffle (bottom) the other is the top. I made

them 17 inches in diameter to cover the 1/2 inch thick

tube walls. I should have made them larger so that they

stand a little proud of the walls. This would help hide

any irregularity between the endcaps and the tube wall. Mill

the two outer round pieces from cabinet grade plywood.

One is the baffle (bottom) the other is the top. I made

them 17 inches in diameter to cover the 1/2 inch thick

tube walls. I should have made them larger so that they

stand a little proud of the walls. This would help hide

any irregularity between the endcaps and the tube wall.

- We

now have one small and one large circle for both the

top and bottom. My circle cutting jig uses a 1/4 inch

hole as the center pivot point. This lets me use a 1/4

inch dowel to align each pair of circles at their centers.

-

Pick

one of the outer pieces to be the top - probably the

better looking one; put that one aside. Align and two

bottom pieces together to make the baffle. I used regular

yellow wood glue. Clamp and let dry overnight. Pick

one of the outer pieces to be the top - probably the

better looking one; put that one aside. Align and two

bottom pieces together to make the baffle. I used regular

yellow wood glue. Clamp and let dry overnight.

- Complete the top endcap.

- I

used two 3/8 inch diameter metal rods to secure the

two endcaps to the tube and to one-another. Having rods

means that the top and bottom should be aligned relative

to each other. Mark a line on both ends of the tube.

Make sure these marks form a line that is perpendicular

to the top and bottom circular plane.

- Align

the top's inner (smaller) circle with the glued up bottom

assembly and temporarily clamp in place. Drill from

the baffle side (to avoid splitting the good outside

surface) a 3/8 inch hole through all layers. I used

a drill press to get a nice perpendicular hole. Use

a brad point bit to minimize damaging the entry hole.

My holes were 1-1/4 inches from the outer edge of the

baffle. Make sure to place the holes to avoid obstructions

with the driver, port, tube, etc.

- On

the bottom baffle, the rods stick out and that's ok.

On the top, they can't stick out for aesthetic reasons.

The nuts on the top endcap must therefore be hidden

between the top two circles (which is why they've not

been glued together yet).

- Remove

the top's inner (small) circle from the clamps. Now

clamp it to the top's outer (larger) circle and mark

the center of the 3/8 inch holes on the outer circle.

Use another 1/4 inch dowel for alignment.

- It's

probably a good idea to label the 2 rods, especially

if they are not exactly opposite each other on a diameter.

I marked all holes with a "1" and "2".

- Mill

a recess between the two circles that make up the top

endcap. The nuts for the rods will be hidden here. On

the top's inner (smaller) circle, use a 1-1/4 inch diameter

Forstner bit to drill a recess about halfway into the

plywood. This is on the side that will meets the top's

outer circle. The recess must be wide enough to handle

a flat washer.

- On

the top's outer circle, use a 3/4 inch forstner bit

to do the same, using the previously marked center as

a guide. This recess is narrower since it only has to

conceal the 3/8 inch nut, not the washer. The total

depth of both recesses must hold a flat washer, lock

washer and nut.

- Since

the top's smaller circle is now thinner at the hole

due to the recess, I added reinforcement. I glued an

additional layer of plywood to the inside plywood face

and drilled a 3/8 inch hole through it.

- Cut

down the steel rods to the desired length. I did a dry

fit of everthing to get just the right length. I used

a hacksaw, and filed the rough end smooth for safety.

-

If cutting the rod leaves that end unusable for threading

a nut and you can't fix it with a grinder, insert a

nut, lock washer and washer from the other end. The

bad end will be the end that's enclosed between the

two top circles and will remain unseen and unused. Thread

the rod from the top, through the top's small circle.

From the other side, add another washer, lock washer,

and nut. Tighten the nuts such that the top nut assembly

fits in the cavity previously drilled.

If cutting the rod leaves that end unusable for threading

a nut and you can't fix it with a grinder, insert a

nut, lock washer and washer from the other end. The

bad end will be the end that's enclosed between the

two top circles and will remain unseen and unused. Thread

the rod from the top, through the top's small circle.

From the other side, add another washer, lock washer,

and nut. Tighten the nuts such that the top nut assembly

fits in the cavity previously drilled.

- With

both rods in place and secured, the top's larger circle

can be aligned with the smaller circle and the recesses

milled into it should cover the protruding 3/8 inch

nuts. If the recesses are too small, take out the drill

and recess deeper, being careful not to cut through

to the other side.

- Align,

glue and clamp the two top pieces together. What I forgot

to do is to fill the void around the nuts assembly with

filler - silicone caulk would have worked. I didn't

realize this until much later and it was too late to

take the assembly apart.

- Drill

3/8 inch hole over the 1/4 inch dowel that's sticking

out of the top piece (outside face). Make 3/8 inch plug

from the appropriate wood using a plug cutter to plug

the hole. This step is purely for looks.

- Add

6 layers of roofing felt on the inside of the top assembly.

These are held by caulk and a few screws. This adds

additional damping on the surface directly opposite

the driver. Total thickness is about 3/8 inch. Why 6

layers you ask ? Because that's what I had on-hand !

-

What I should have done was to attach bracing to the top

endcap to stiffen it. Then attach the roofing felt to

any remaining flat surfaces. This is probably the single

most important step I omitted during construction.

What I should have done was to attach bracing to the top

endcap to stiffen it. Then attach the roofing felt to

any remaining flat surfaces. This is probably the single

most important step I omitted during construction.

- The

top assembly is now done.

- Complete the bottom endcap (the baffle).

- Now

it's time to work on the bottom endcap, which is also

the baffle. Plan the placement of the driver, port,

terminal cup, bracing and feet onto the baffle.

- Route

a circle into the baffle for the driver's flange. This

is 10-1/8 inch in diameter and 3/16 inch deep. The depth

allows for a gasket to be added.

- Route

the driver opening.This is 9 inch in diameter. For safety,

do this in multiple passes, leaving about 1/4 inch at

the bottom. Remove the remaining 1/4 inch with jigsaw

for safety.

- Mill

3-5/16 inch diameter hole for the plastic port using

a T-shaped circle cutter on a drill press. Like the

driver opening, cut as far down as possible without

going through, remove remainder with jigsaw.

-

Cut a 2-7/8 x 2-1/8 inch opening for a rectangular terminal

cup. Do this with a jigsaw.

Cut a 2-7/8 x 2-1/8 inch opening for a rectangular terminal

cup. Do this with a jigsaw.

-

Glue and screw a hardwood bar on the inside of the baffle.

This bracing helps stiffen the baffle, compensating

for the loss of so much material that's been removed.

Depending on the layout of holes on the baffle, there

may not be room for any bracing, or multiple braces

may have to be used. The particle board I used was pretty

good material. Void-free plywood would have been structurally

stronger.

Glue and screw a hardwood bar on the inside of the baffle.

This bracing helps stiffen the baffle, compensating

for the loss of so much material that's been removed.

Depending on the layout of holes on the baffle, there

may not be room for any bracing, or multiple braces

may have to be used. The particle board I used was pretty

good material. Void-free plywood would have been structurally

stronger.

- Add

alignment marks to both the top and bottom endcap assemblies.

These will be used to align top and bottom with the

mark on the tube.

- Work on the cardboard tube.

- The

cardboard tube's outer skin is a spiral layer of thick

paper/cardboard. Each winding of the spiral overlaps

the previous one by a little bit. To make the tube completely

smooth, these overlapping regions must be made flush

with the rest of the tube. Shave (with a block plane)

the overlapping regions of the cardboard tube. Sand

as needed.

- Use

vinyl spackle to patch up all rough areas and other

dinks, scratches, etc. (this was after all a surplus

tube). Sand the result to 220 grit sandpaper.

-

Prime the exterior tube surface with a spray primer.

Prime the exterior tube surface with a spray primer.

-

Spray the exterior with 2 cans of Rustoleum's Stone Creations

(greenish tint). Seal with one can of Rustoleum American

Accent matte finish clearcoat.

Spray the exterior with 2 cans of Rustoleum's Stone Creations

(greenish tint). Seal with one can of Rustoleum American

Accent matte finish clearcoat.

- At this

point, I evaluated the appearance of the endcaps. The top

was furniture grade plywood, but I wanted a cherry look

to better contrast with the granite green finish of the

tube. The veneer was birch, and when I applied a cherry

stain, it looked horrible. So I decided to add another layer

of cherry veneer plywood I already had.

- Glue

3/8 inch thick cherry veneered plywood to the top endcap.

Use a router with a pattern following bit to cut the

plywood flush with the existing endcap.

- For

the exposed edges, apply cherry edge banding to both

endcaps. This is an iron-on strip of real wood veneer

with pre-applied, heat activated glue.

- Applied

Watco Danish oil to cherry surfaces. Topcoat with a

thin layer of wax.

- Final assembly.

- Glue

the plastic port tube to the bottom endcap/baffle using

RooClear plastic glue.

- Attach

two wires from the inside of the terminal cup. Solder

connectors to the driver ends of the wires to allow

easy connect/disconnect to/from the driver.

- Mount

the rectangular terminal cup to bottom endcap/baffle

with four screws. Use a small amount of rope caulk to

give it a good seat in the hole.

- Connect

the endcaps to the tube. On the first pass, I used rope

caulk to seal the endcap/tube interface. Later I glued

the tube to the endcaps making it effectively impossible

to disassemble the unit without destroying something.

Add a flat washer, lock washer and tighten the nuts

on the rods.

- Feet

-

To raise the unit off the ground (after all, this is a

downward firing sub) I made feet out of 4 hardwood balls.

These have a flat part and are sold as doll heads in

craft stores (they may also be sold for other purposes).

The ones I used are 3 inches in diameter.

To raise the unit off the ground (after all, this is a

downward firing sub) I made feet out of 4 hardwood balls.

These have a flat part and are sold as doll heads in

craft stores (they may also be sold for other purposes).

The ones I used are 3 inches in diameter.

- To

mount the flat part of the ball to the baffle, I made

a drilling jig. I drilled a 3/8 inch diameter hole through

a block of scrap wood to make the jig. The purpose of

the jig is to guide a drill bit perpendicularly into

the ball.

- Locate

the center of each ball's flat area. Position the hole

of the jig over the center of each foot and using the

jig as a drilling guide, drill a 3/8 inch diameter hole

about 1-1/2 inch deep hole into each ball.

-

Cut four lengths of 3/8 inch threaded rod from stock left-over

from the main conneting rods. These should be long enough

to go from the balls, through the baffle, and stick

out the other side with clearance for a flat washer,

lock washer and nut assembly.

Cut four lengths of 3/8 inch threaded rod from stock left-over

from the main conneting rods. These should be long enough

to go from the balls, through the baffle, and stick

out the other side with clearance for a flat washer,

lock washer and nut assembly.

- Epoxy

a piece of 3/8 inch threaded rod into each ball.

- To

locate the four feet accurately on the baffle, I made

another jig. This was 2 pieces of wood, half-lapped

onto one-another at right angle (makes a large '+' sign).

I marked off the radius from the center of the jig and

moved the jig about the baffle until all four sides

were equi-distant from the center based on the markings.

- Drill

3/8 inch diameter holes through the baffle for the feet

- Mount

and secure the feet with a flat washer, lock washer

and nut on the inside of the tube. Reach in through

the driver opening to do this.

- Lastly.

- Vaccum

out the interior in case there's debris still hiding

in there.

- Mount

driver to the baffle. The supplied gasket is pretty

useless so use rope caulk. Connect the wiring, then

screw the driver down.

- Retraced steps.

- As

noted in the results section below, there was

excessive vibration on the tube and top endcap. I decided

to take the tube assembly apart and try and damp out

the vibration without having to rebuild the endcaps.

I added a layer of 6 lb carpet padding to the inside

surface of the tube. This was glued in place.

- The

tube was then glued to the endcaps with Liquid Nails

construction adhesive.

Building the Amplifier

There wasn't

much to do on the Parapix amplifier. The modules arrived almost

ready to use. Here's what I did :

- Modifications

to the amplifier.

- The

best place to obtain infomation on the Parapix amp is

on the Apex

Jr. web page.

- I

used a 48 VCT 3 Amp transformer, which mounted directly

to the component side of the Parapix faceplate on two

of the existing mouting holes.

- For

the power wiring harness, I connected five of the six

wires (two for the primary, three for the seconday of

the transformer). I decided not to wire pin 1.

- The

amp jumper is set to bridge mode.

- Since

the amp is external to the subwoofer, I needed two connectors

for the amp's output. I mounted a pair of 5-way binding

posts from Radio

Shack to the faceplate where the Paramount logo

sits. I spaced them 3/4 inch apart for use with standard

dual plugs.

- Next

to the Peak LED (between the two knobs), I drilled

a 1/4 inch hole and mounted a plastic T1-3/4 LED retainer

to hold the Power LED.

-

Next to the LEDs, I mounted a SPDT switch. Three wires from

the switch were connected to a pair of headers salvaged

from the original metal housing (see below). These headers

go to the three pins of the boost circuitry. This allows

the user to enable or disable the boost rather than

hiding this feature on the amplifier PCB. Make sure

to mount the boost switch to make sense - up for boost

on, down for boost off.

Next to the LEDs, I mounted a SPDT switch. Three wires from

the switch were connected to a pair of headers salvaged

from the original metal housing (see below). These headers

go to the three pins of the boost circuitry. This allows

the user to enable or disable the boost rather than

hiding this feature on the amplifier PCB. Make sure

to mount the boost switch to make sense - up for boost

on, down for boost off.

- Housing for the amplifier.

-

The metal casing is from an old Exabyte 8 mm tape drive

whose mechanisms have long ago seen the local land fill.

The only parts I kept were the 3 sided metal casing

and some wiring (see above).

The metal casing is from an old Exabyte 8 mm tape drive

whose mechanisms have long ago seen the local land fill.

The only parts I kept were the 3 sided metal casing

and some wiring (see above).

- For

the two ends, I milled endcaps much like the subwoofer

(of course !). Each endcap has a solid cherry outer

piece and a smaller particle board inner piece. The

inner piece is screwed to the outer cap and also to

the metal casing.

- The

amplifier module is mouted to the inner particle board

pieces with screws.

-

Black spray paint and a clearcoat was applied to the metal

casing to match the black Parapix faceplate. The cherry

endcaps received a coating of Danish oil and wax; same

as the subwoofer.

Black spray paint and a clearcoat was applied to the metal

casing to match the black Parapix faceplate. The cherry

endcaps received a coating of Danish oil and wax; same

as the subwoofer.

Results

To test

the subwoofer, I used the line level output of my PC sound

card (Turtle Beach Malibu)

to drive a Rotel amplifier. Later I repeated this test with

the Parapix amp. This particular sound card has decent low

end extension (see test results at the PC

AV Tech web site) so I wasn't worried that it would limit

the low end test signal.

When I cranked

the volume up, I noticed that the tube wall and top endcap

vibrated. This should not happen with a tubular enclosure.

Adding mass to the top decreased the vibration; sitting on

it removed all of it. I concluded that I did not do an adequate

job of strengthening the top endcap - there was no bracing,

the inner circle was low grade plywood, and as mentioned previously,

I had neglected to fill the void where the nuts are hidden.

I tried

to do what I could short of ripping things apart. I glued

the tube to the endcaps, and added carpet padding to the tube

walls. This seemed to help a wee bit, but the walls still

vibrated. The real solution was to rebuild the endcap. Since

I didn't have the time to do this, I decided to place the

subwoofer into service and worry about it some other time

- hey, this is DIY, which means things are never really done

!

No measurements

were ever made. Instead I simply listened, looked,and felt

the results. It was pretty obvious that the frequency response

cutoff was in the mid to upper 20's as predicted. As for SPL,

it can definitely crank but it didn't take much to reach the

driver's excursion limit. Nonetheless, the SPL at that point

is more than enough for HT use in a "typical" room.

|

|

29-September-2000

Note: The

contents in these pages are provided without any guarantee,

written or implied. Readers are free to use them at their

own risk, for personal use only. No commercial use is allowed

without prior written consent from the author.

|

|

|